|

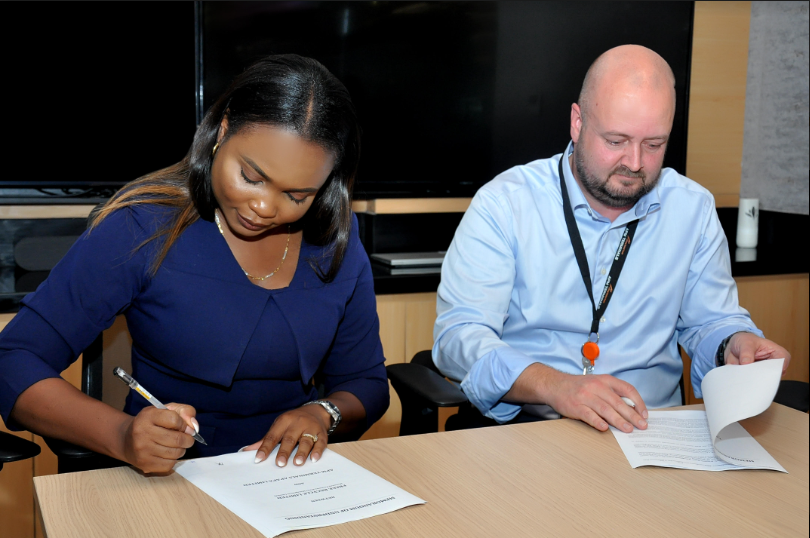

| EGCS Director, Donald Gregory |

In less than 70 days the

International Maritime Organization’s 2020 sulphur cap will kick in, bringing

with it a number of changes in the shipping industry.

Of the various compliance solutions

available on the market, exhaust gas cleaning systems (EGCS), also known as

scrubbers, are ranked as a popular choice for both existing and new build

vessels.

The key factors behind their popularity include financial benefit,

simplicity with regard to installation and a relatively short return on

investment.

simplicity with regard to installation and a relatively short return on

investment.

On the other hand, there are cases

where installing scrubbers is not a viable solution, such as lower fuel

consumption ships that don’t enjoy the rate of savings as ships operated with

EGCS and therefore have a longer payback. In a few cases, space and other

technical factors can play a part in the decision not to scrub.

where installing scrubbers is not a viable solution, such as lower fuel

consumption ships that don’t enjoy the rate of savings as ships operated with

EGCS and therefore have a longer payback. In a few cases, space and other

technical factors can play a part in the decision not to scrub.

According to the latest estimates

from the Exhaust Gas Cleaning System Association (EGCSA), there will be at

least 4,000 ships fitted with scrubbers in 2020.

from the Exhaust Gas Cleaning System Association (EGCSA), there will be at

least 4,000 ships fitted with scrubbers in 2020.

EGCSA offers technical information

and advice to ship-owners, and participates in forums where regulations are

developed, impact assessments are actioned and evaluated. It is working with

the International Chamber of Shipping (ICS) to form a group of designers and

users to identify and improve quality and performance of EGCS.

and advice to ship-owners, and participates in forums where regulations are

developed, impact assessments are actioned and evaluated. It is working with

the International Chamber of Shipping (ICS) to form a group of designers and

users to identify and improve quality and performance of EGCS.

The scrubber installations have

gravitated towards the larger vessels and vessels with high installed power

where the economics of the investment versus the lower fuel cost are projected

to give a high rate of return.

gravitated towards the larger vessels and vessels with high installed power

where the economics of the investment versus the lower fuel cost are projected

to give a high rate of return.

The majority of the installations use

sea water as the process fluid and discharge the treated and continuously

monitored water overboard, in other words so-called open loop EGCS.

sea water as the process fluid and discharge the treated and continuously

monitored water overboard, in other words so-called open loop EGCS.

However, with the need to decarbonize

the shipping industry and the development of alternative marine fuels,

including zero-emission fuels, scrubbers have not been identified as a

long-term solution, with some market analysts predicting their life-span not to

exceed ten years.

the shipping industry and the development of alternative marine fuels,

including zero-emission fuels, scrubbers have not been identified as a

long-term solution, with some market analysts predicting their life-span not to

exceed ten years.

The association begs to differ,

saying that the demand for scrubbers would last for at least the next 30 years.

saying that the demand for scrubbers would last for at least the next 30 years.

Speaking with World Maritime News,

the EGCSA Director, Donald Gregory, explained that with the development of new

fuels, scrubbers “may well evolve into much more advanced and sophisticated

systems which purify the air that is discharged. The market life expectancy of

current scrubbers removing SOx is at least another 10 years.”

the EGCSA Director, Donald Gregory, explained that with the development of new

fuels, scrubbers “may well evolve into much more advanced and sophisticated

systems which purify the air that is discharged. The market life expectancy of

current scrubbers removing SOx is at least another 10 years.”

“Carbon is an almost inevitable

molecule of solid and liquid fuels that are easily transportable and managed.

What may change is the source of the carbon, i.e. not from fossil, so I am

doubtful about decarbonization,” Gregory said, referring to the scrubber

market’s way forward on the heels of the establishment of Getting to Zero

Coalition through which industry leaders such as Maersk, Norden, ABS etc,

committed to leading the push for shipping’s decarbonization.

molecule of solid and liquid fuels that are easily transportable and managed.

What may change is the source of the carbon, i.e. not from fossil, so I am

doubtful about decarbonization,” Gregory said, referring to the scrubber

market’s way forward on the heels of the establishment of Getting to Zero

Coalition through which industry leaders such as Maersk, Norden, ABS etc,

committed to leading the push for shipping’s decarbonization.

Touching upon the market readiness

for 2020, Gregory said that many owners have not done their due diligence or

have only half done it. There has also been uncertainty about fuel pricing, but

risk and deriving advantage from it has been the shipowners’ bread and butter

for years, Gregory continued.

for 2020, Gregory said that many owners have not done their due diligence or

have only half done it. There has also been uncertainty about fuel pricing, but

risk and deriving advantage from it has been the shipowners’ bread and butter

for years, Gregory continued.

Speaking about a wide-spread belief

that scrubbers “simply transfer the pollution produced by vessels from the air

to the ocean,” EGCSA director said that published evidence from research

indicates that air quality is improved by removing SOx from the air through

exhaust gas cleaning systems, adding that “the current status quo is that HSFO

and distillate fuel emissions to air eventually settle in the sea.”

that scrubbers “simply transfer the pollution produced by vessels from the air

to the ocean,” EGCSA director said that published evidence from research

indicates that air quality is improved by removing SOx from the air through

exhaust gas cleaning systems, adding that “the current status quo is that HSFO

and distillate fuel emissions to air eventually settle in the sea.”

“By using an EGCS, the exhaust gases

are scrubbed and particulate in the scrubbed water is treated as necessary to

ensure the water discharged meets the strict and continuously monitored

International Maritime Organisation (IMO) limits. EGCSA has carried out water

sampling as have many other organisations. None of the research indicates

significant exceedances of the IMO limits or for that matter other standards

such as the World Health Organisation (WHO) water quality standards.

are scrubbed and particulate in the scrubbed water is treated as necessary to

ensure the water discharged meets the strict and continuously monitored

International Maritime Organisation (IMO) limits. EGCSA has carried out water

sampling as have many other organisations. None of the research indicates

significant exceedances of the IMO limits or for that matter other standards

such as the World Health Organisation (WHO) water quality standards.

“Long-term studies at power stations,

oil refineries and even the Port of Rotterdam have not identified any impact of

scrubber process water on the environment in the water.”

oil refineries and even the Port of Rotterdam have not identified any impact of

scrubber process water on the environment in the water.”

When asked about the early teething

issues that were reported with scrubbers, EGCSA said that incidents such as

corrosion and water discharge into the auxiliary engine had been dealt with

through design alterations. After years of development, the systems are today

made of high-grade stainless steel and have an expected life of over 30 years.

issues that were reported with scrubbers, EGCSA said that incidents such as

corrosion and water discharge into the auxiliary engine had been dealt with

through design alterations. After years of development, the systems are today

made of high-grade stainless steel and have an expected life of over 30 years.

The requirements for EGCS today

include new types of materials such as glass reinforced plastic pipes, special

stainless steels, hull coatings, use of monitoring equipment etc. These are all

reliable and long lasting if the installations are undertaken by fabricators

and installers with the appropriate experience and expertise, the association

said.

include new types of materials such as glass reinforced plastic pipes, special

stainless steels, hull coatings, use of monitoring equipment etc. These are all

reliable and long lasting if the installations are undertaken by fabricators

and installers with the appropriate experience and expertise, the association

said.

Commenting on the recent bans on

open-loop scrubbers by some of the world’s major ports, Gregory said that the

decision-making process lacked science- or fact- based justification.

Nevertheless, he doesn’t believe such decisions could jeopardize the take-up of

EGCS to a major degree since ships fitted with scrubbers can easily switch over

fuels to comply with the bans when entering the ports in question.

open-loop scrubbers by some of the world’s major ports, Gregory said that the

decision-making process lacked science- or fact- based justification.

Nevertheless, he doesn’t believe such decisions could jeopardize the take-up of

EGCS to a major degree since ships fitted with scrubbers can easily switch over

fuels to comply with the bans when entering the ports in question.

As explained, the majority of a

ship’s fuel consumption occurs while it is in deep sea where it can comply with

the sulphur cap by means of an EGCS.

ship’s fuel consumption occurs while it is in deep sea where it can comply with

the sulphur cap by means of an EGCS.

“Well, uncertainty never helps in any

business decision. So far, the calculated risk and reward balance seems to

continue to be in favour of the flexibility and cost savings provided by EGCS,”

he concluded.

business decision. So far, the calculated risk and reward balance seems to

continue to be in favour of the flexibility and cost savings provided by EGCS,”

he concluded.

Speaking on the way forward to a more

environmentally-friendly future of the sector, Gregory noted that ports and

shippers need to take responsibility for their actions and support development,

adding that CO2 emissions “need to be measured and charged at a rate of at

least USD 150/tonne.”

environmentally-friendly future of the sector, Gregory noted that ports and

shippers need to take responsibility for their actions and support development,

adding that CO2 emissions “need to be measured and charged at a rate of at

least USD 150/tonne.”

“There needs to be a cap on carbon

emissions derived from fossil sources. Then there is the question of where the

energy on board the ship is going to come from? Nuclear seems to be a sensible

and coherent option as do liquid fuels.

emissions derived from fossil sources. Then there is the question of where the

energy on board the ship is going to come from? Nuclear seems to be a sensible

and coherent option as do liquid fuels.

“If fuel cells are not up to the job,

then IC engines fuelled by hydrogen and carbon where the carbon

has been recovered from the atmosphere may be a solution. This is a question

that has so many aspects to it that potential answers to it could fill an

entire magazine.”

then IC engines fuelled by hydrogen and carbon where the carbon

has been recovered from the atmosphere may be a solution. This is a question

that has so many aspects to it that potential answers to it could fill an

entire magazine.”

World Maritime News